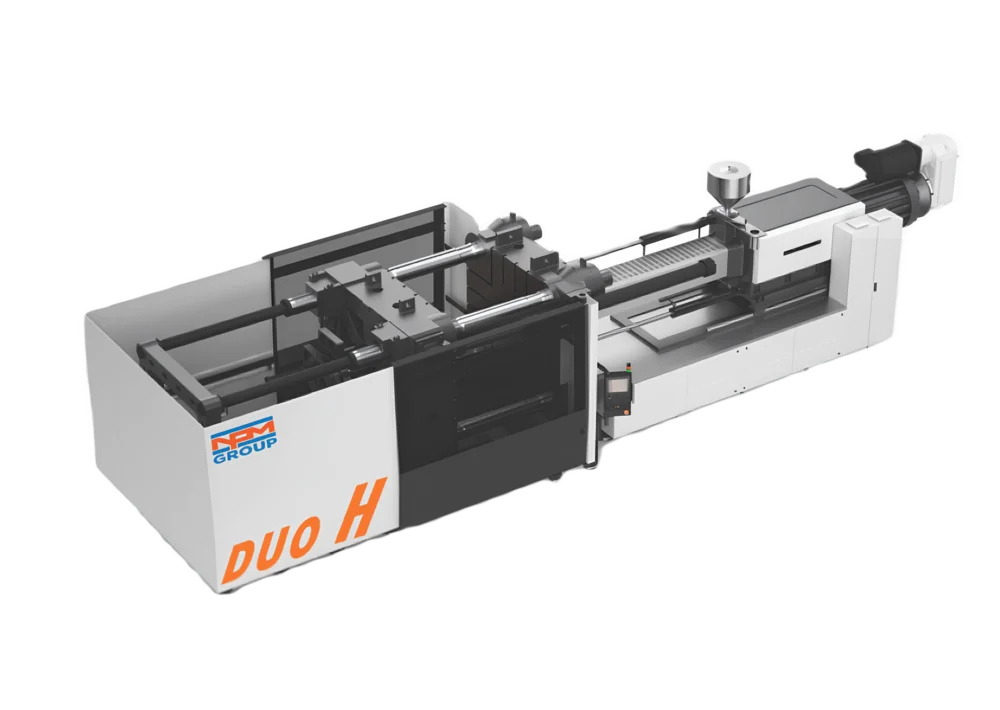

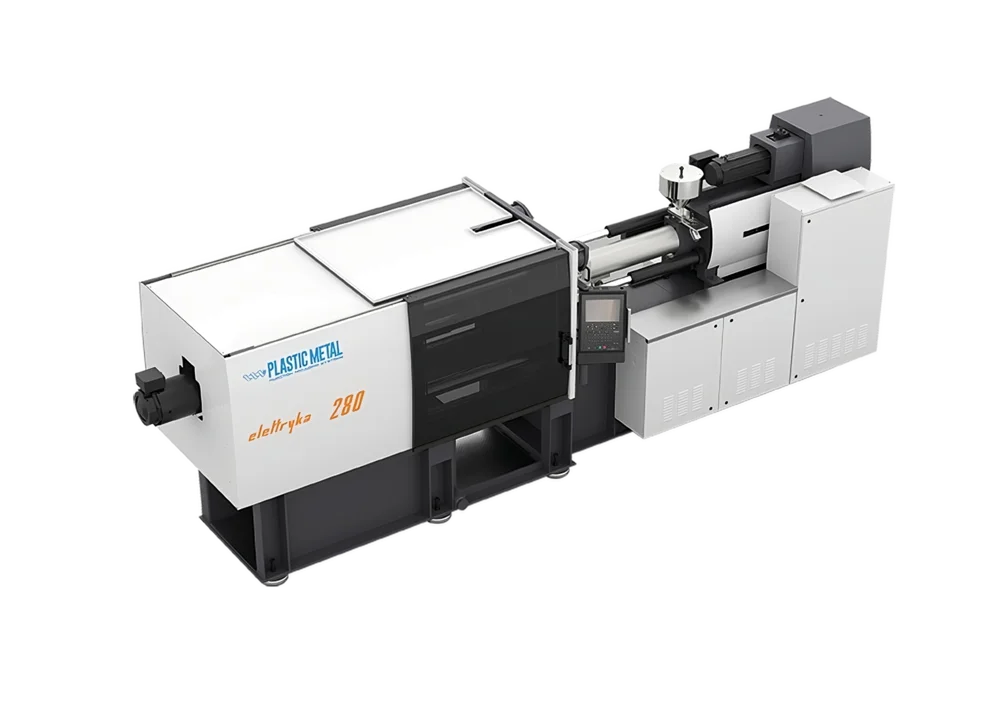

Full electric injection molding machine

Elettryka

ELETTRYKA is an innovative range of “full electric” injection moulding machines in the range from 50 to 1000 tons.

Desideri saperne di più su come i nostri prodotti possono migliorare la tua produzione?

Richiedi maggiori informazioni oggi stesso e scopri come Plastic Metal può aiutarti a raggiungere risultati straordinari.

The Full Electric revolution: efficiency, energy saving, sustainability for high quality products

All movements are electrically operated. In addition to the usual characteristics such as strength reliability and advanced technology. Elettryka achieves a drastic reduction of energy consumption ensuring the best performance in terms of production efficiency and precision.

Moreover, the optimization of the design and the careful research of the components help to reduce operating costs and maintenance.

Advantages of Elettryka

Maximum system reliability

Cost reduction

Guaranteed energy savings

Simultaneous movements

5 point toggle clamping system

The five movements

The injection unit is controlled through ball screws driven by brushless servomotor and allows exceptional precision of repeatability of the moulded parts. The generous dimensions of mechanical structure ensure great reliability of the system in time. The injection movement may be faster than the closing force generated, thus reducing the cycle time. The control of hold-on pressure and back-pressure is ensured by the feed-back of the load cell of the system.

The movement of the injection unit is performed by two ball screws driven by a brushless inverter-controlled motor. This motor is selfbraking and once the position has been reached there is no need for signals which means further energy saving. The double screw system allows a symmetric application of the nozzle contact force.

Two ball screws driven by a brushless motor allow to keep the central plate ejector area clear for easy access to the mould fitting.

The screw rotation of the screw is operated by an electric motor. This high torque brushless motor allows the best performance of the movement ensuring optimization of the plasticizing process also for “hard” thermo polymers. The water cooled motor is operated by a drive that allows to use only the energy required for the screw charge. It also allows simultaneous movements.

The mechanical structure of the clamping unit is characterized by a 5-point double toggle with steel links and special bronze bushings and a multiple point lubrication system with programmable cycles and safety devices. The clamping movement is performed by an electromechanical axis that exploits a ball screw. The rotation of the system is provided by a brushless motor specially designed with a hollow shaft installed directly on axis. The motor, developed in cooperation with Moog, provides the system with torque and speed that result in a very fast and precise mould movement , perfectly controlled in acceleration and braking. At the same time it ensures an excellent control of “ mould safe”. The lubrication of the ball screw is entrusted to a special pump, with recovery of lubrication oil. The water cooled motor is also monitored by thermal sensors that control and ensure the optimal temperature of the whole system.

REQUEST MORE INFO

Fill in the form, we’ll answer as soon as possible.